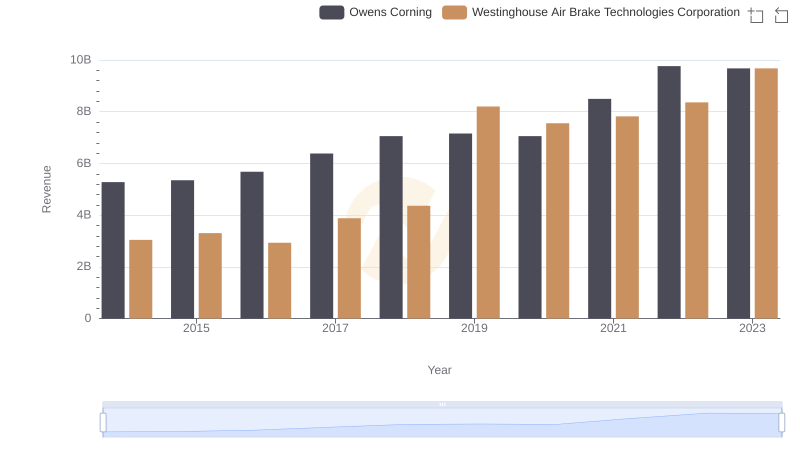

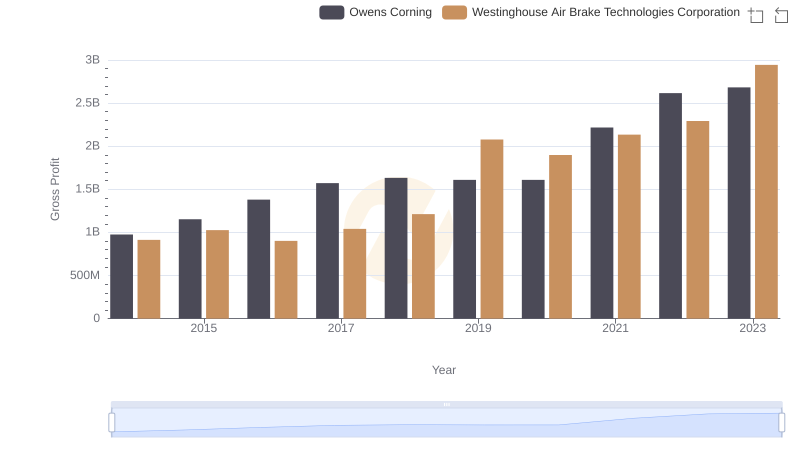

| __timestamp | Owens Corning | Westinghouse Air Brake Technologies Corporation |

|---|---|---|

| Wednesday, January 1, 2014 | 4300000000 | 2130920000 |

| Thursday, January 1, 2015 | 4197000000 | 2281845000 |

| Friday, January 1, 2016 | 4296000000 | 2029647000 |

| Sunday, January 1, 2017 | 4812000000 | 2841159000 |

| Monday, January 1, 2018 | 5425000000 | 3151816000 |

| Tuesday, January 1, 2019 | 5551000000 | 6122400000 |

| Wednesday, January 1, 2020 | 5445000000 | 5657400000 |

| Friday, January 1, 2021 | 6281000000 | 5687000000 |

| Saturday, January 1, 2022 | 7145000000 | 6070000000 |

| Sunday, January 1, 2023 | 6994000000 | 6733000000 |

| Monday, January 1, 2024 | 7021000000 |

Igniting the spark of knowledge

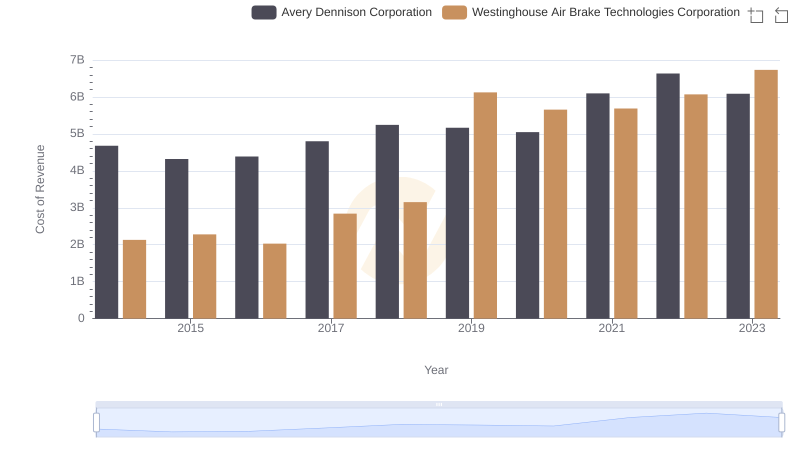

In the ever-evolving landscape of industrial efficiency, the cost of revenue is a critical metric. From 2014 to 2023, Westinghouse Air Brake Technologies Corporation and Owens Corning have demonstrated distinct trajectories in managing their cost of revenue. Owens Corning, a leader in building materials, has seen a steady increase, peaking at approximately 7.1 billion in 2022, reflecting a 66% rise from 2014. Meanwhile, Westinghouse Air Brake Technologies, a key player in rail technology, experienced a more volatile journey, with costs surging by over 200% from 2014 to 2023, reaching around 6.7 billion. This divergence highlights the contrasting operational strategies and market dynamics faced by these industrial giants. As businesses navigate the complexities of cost management, these insights offer valuable lessons in balancing growth and efficiency.

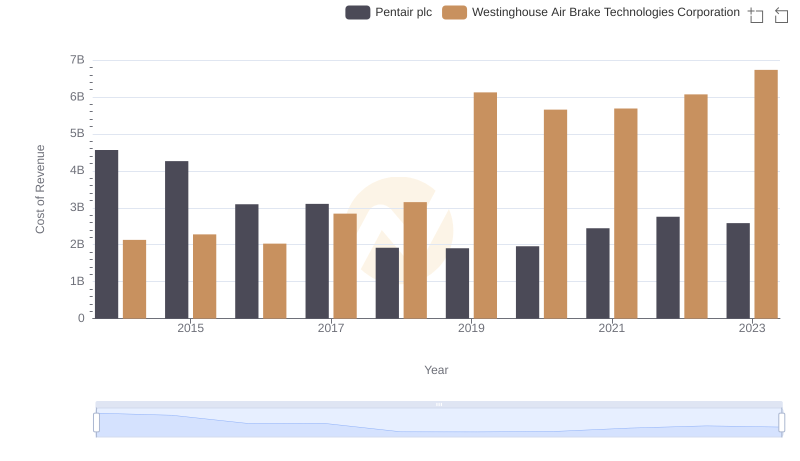

Analyzing Cost of Revenue: Westinghouse Air Brake Technologies Corporation and Pentair plc

Annual Revenue Comparison: Westinghouse Air Brake Technologies Corporation vs Owens Corning

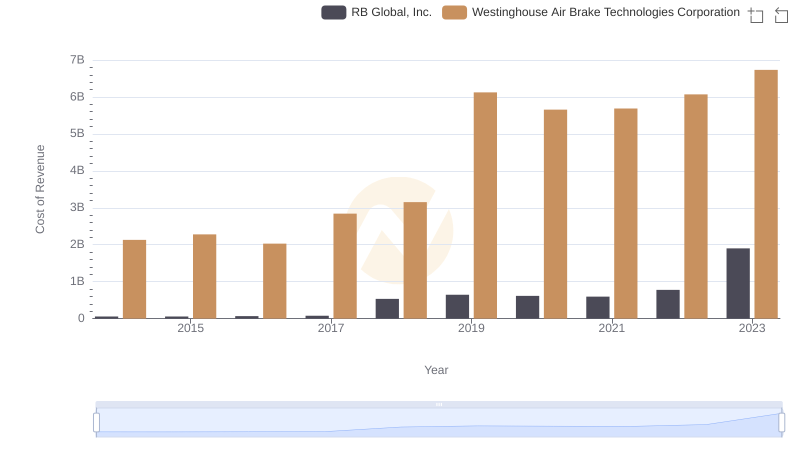

Comparing Cost of Revenue Efficiency: Westinghouse Air Brake Technologies Corporation vs RB Global, Inc.

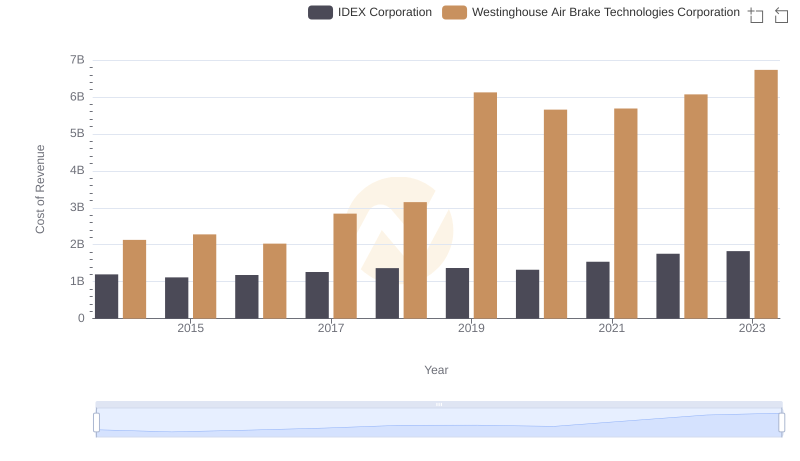

Comparing Cost of Revenue Efficiency: Westinghouse Air Brake Technologies Corporation vs IDEX Corporation

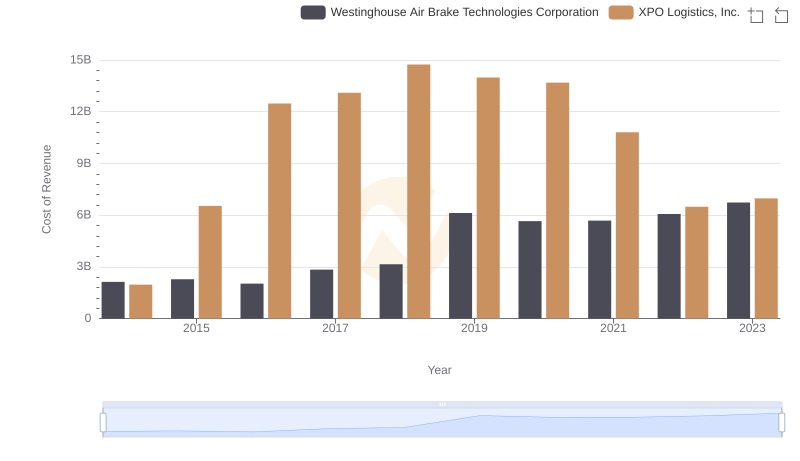

Cost of Revenue Trends: Westinghouse Air Brake Technologies Corporation vs XPO Logistics, Inc.

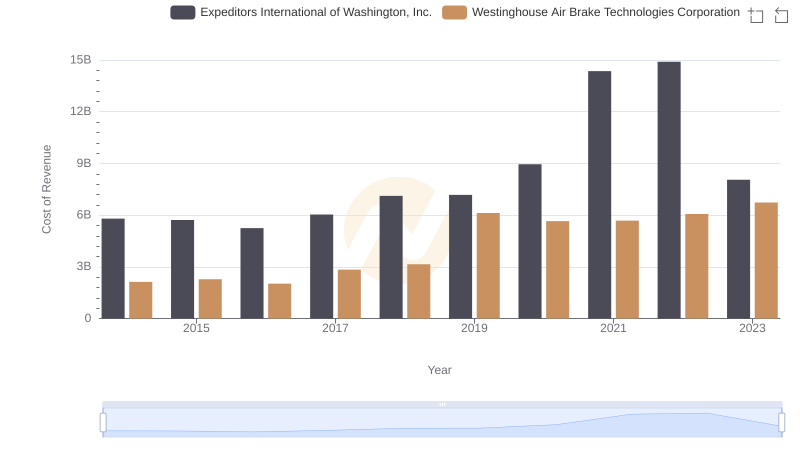

Cost of Revenue Trends: Westinghouse Air Brake Technologies Corporation vs Expeditors International of Washington, Inc.

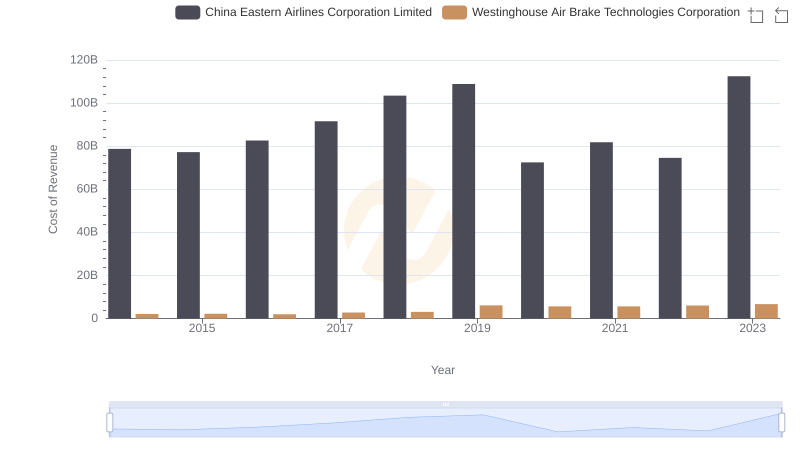

Cost of Revenue Trends: Westinghouse Air Brake Technologies Corporation vs China Eastern Airlines Corporation Limited

Gross Profit Analysis: Comparing Westinghouse Air Brake Technologies Corporation and Owens Corning

Cost of Revenue Trends: Westinghouse Air Brake Technologies Corporation vs Avery Dennison Corporation

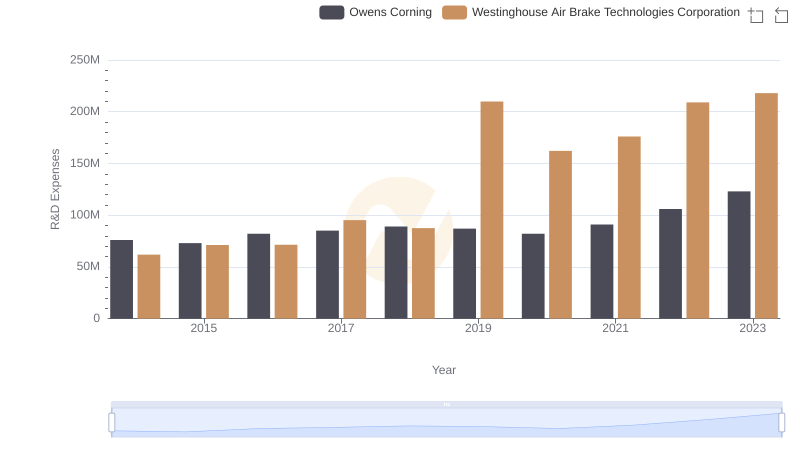

Westinghouse Air Brake Technologies Corporation vs Owens Corning: Strategic Focus on R&D Spending

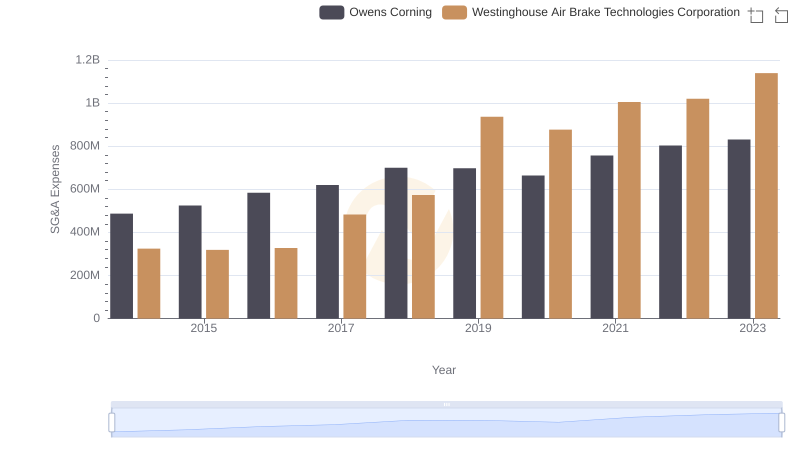

Who Optimizes SG&A Costs Better? Westinghouse Air Brake Technologies Corporation or Owens Corning

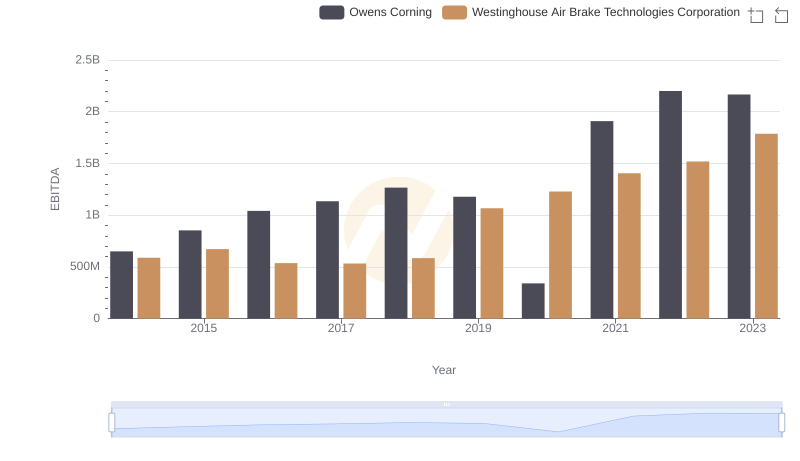

A Side-by-Side Analysis of EBITDA: Westinghouse Air Brake Technologies Corporation and Owens Corning